We're Ready to Serve You

We understand your projects require specific capabilities. We've spent decades growing our expertise and machine options in order to serve a wide variety of needs for our customers.

Engineering

Design for Manufacturing

- Exploring manufacturing methods

- Reducing price

- Prototyping design

3D Modeling and Detailing

- 3D modeling conceptualized designs (Creo/Solidworks)

- Modifying designs

- Creating detailed drawings

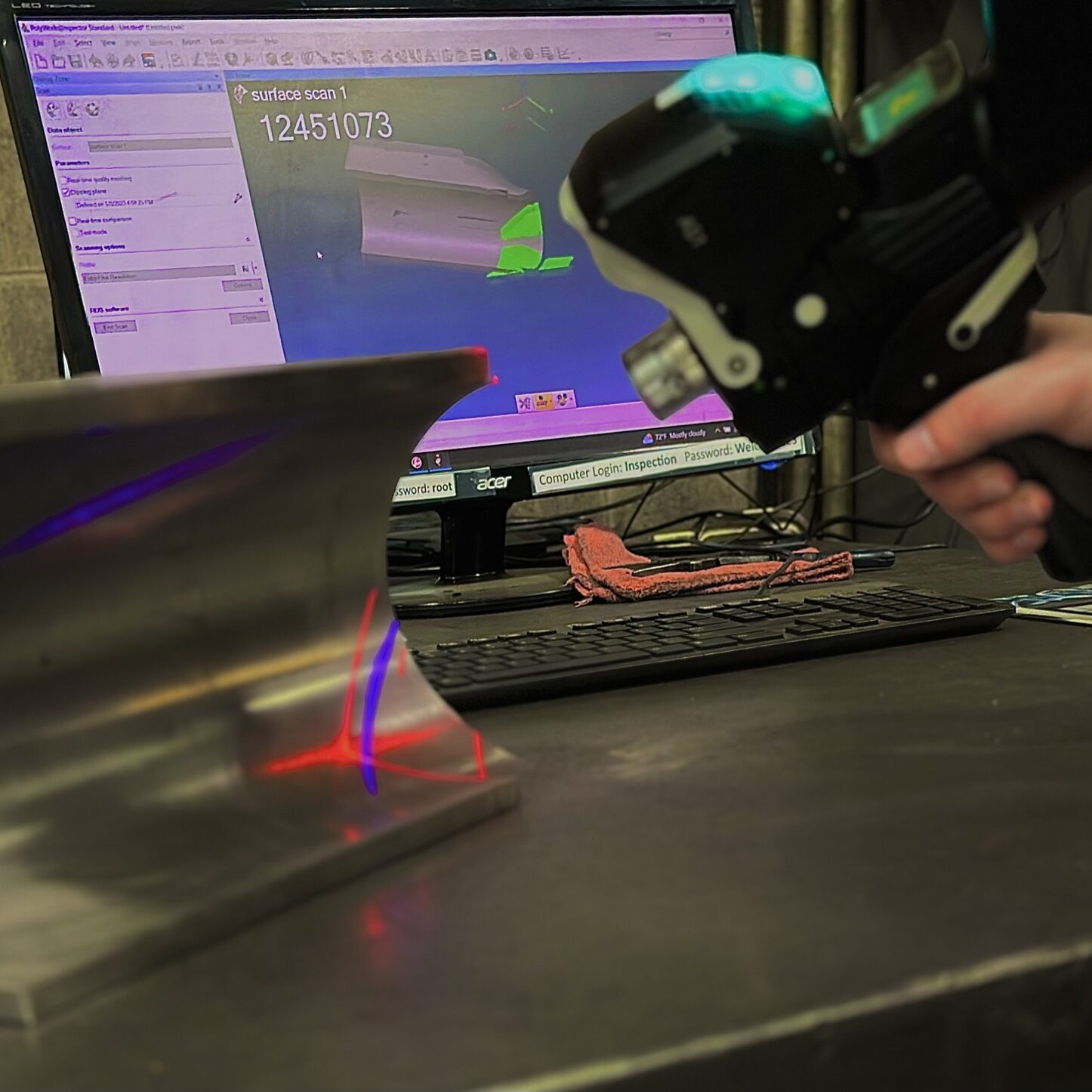

Reverse Engineering

- Probing and scanning part

- Creating model from measured data

Welding

- MIG, pulse MIG, and TIG welding

- Steel, stainless steel (back purging), and aluminum

- Rotary Welding

- Cobot Welding

- Spot Welding

- Bluco tables for modular fixturing setups (accuracy)

Tube Forming

CNC Mandrel Bending

Push Bending

Roll Bending

Round Tubing

- .25" - 14.0" diameter tubing

- Variety of radii at each size

- Mandrels for most common wall thickness

- Carbon Steel, Aluminized Carbon Steel, Stainless Steel, Aluminum

Structural Tubing

- Structural tubing (square and rectangle)

- Variety of bend radii

3D / Tube Lasers

Flat Fiber Laser

- 60" x 120" capable

- Steel (up to 1")

- Stainless Steel (up to 1")

- Aluminum (up to 1")

- Etching

Tube Fiber Lasers

- Round tubing up to 14” Outer Diameter

- Square tubing up to 10"

- Max weight 23.5 lbs/ft

- Max length 27'

- Cuts Angle and C-channel

- Cuts Materials: Steel, Stainless Steel, Aluminum, Copper, and Brass

3D Fiber Laser

- Cuts complex geometries into parts

- Cuts Materials: Steel, Stainless Steel, Aluminum

Laser / Press Brake

Forming Capabilities

- CNC Press Brakes up to 352 tons

- 6 axis CNC back gauges

- 14' bed

- Rolling

- Shearing

- Punching